Under sustainability and profitability initiative, Qatar Steel aims to reduce waste through reuse and recycling. Steel scrap, EAF dust, and EAF slag are the most significant solid waste generated by the steel making operations. As such, Qatar Steel’s focus is to increase the recycling efforts and results in regard to these products.

In 2017, Qatar Steel has successfully dispatched 95,000 metric tonnes of EAF dust to a local cement company for reuse in their operations. Similarly, all scrap is purchased locally, which increases the amount of reused material in operations and decreases the environmental impact of transportation. EAF slag is a major byproduct of the steelmaking process. The use of this slag has been tested in base, sub-base and asphalting of road construction within Qatar Steel’s premises in the Mesaieed Industrial Complex in Qatar. So far, there have been no issues with the performance of the pavement with trafficking. If this continues to be successful, the recycling project will result in partial replacement of imported aggregates for road construction in the State of Qatar.

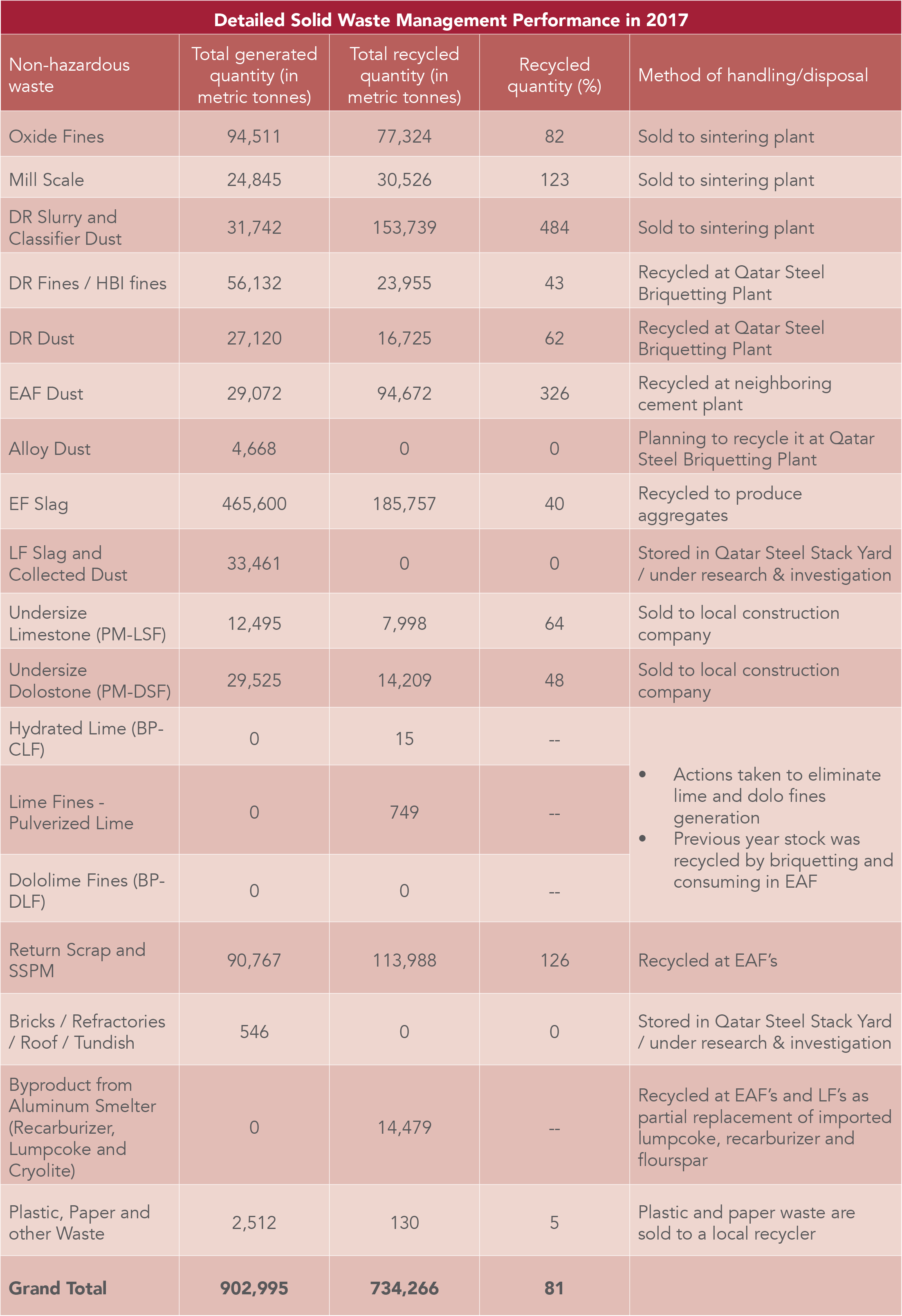

Overall, 733,090 metric tonnes, or 81% of total waste generated, was recycled/sold to a third party in 2017. Since 2015, Qatar Steel has increased the amount of waste recycled/sold to a third party by 140%.

| Waste Management | ||||

|---|---|---|---|---|

|

(in metric tonnes)

|

2015 | 2016 | 2017 | |

| Total waste generated (mt) |

791,410

|

777,441

|

902,995

|

|

| Operational waste generated and disposed of (mt) |

461,573

|

105,273

|

152,147

|

|

| Operational waste generated and sold to third parties as byproducts for reuse or recycling (mt) |

304,505

|

768,805

|

733,090

|

|

|

Percentage of Operational Waste Recycled/Sold to Third Parties

as byproduct for Recycling

|

38%

|

99%

|

81%

|

|

To provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.

Employee Portal

Employee Portal