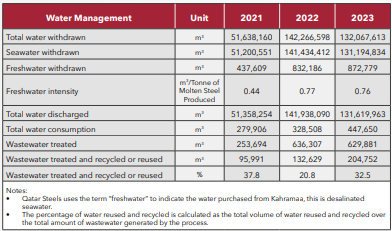

Water and Effluents

In our commitment to operating responsibly within a water-scarce region, Qatar Steel prioritises reducing water consumption for the benefit of our operations, the community, and the environment.Qatar Steel uses water in the form of freshwater, seawater, and recycled water in its operations, mainly as a cooling agent in addition of process requirement. Qatar Steel’s water management approach focuses on three objectives:

• Decrease freshwater consumption,

• Reduce wastewater discharge to sea.

• Increase the recycling rate of processed wastewater.

It is essential to note that our company relies solely on seawater as our primary water source, rather than freshwater resources. We use seawater for cooling purposes during the process and this water is subsequently discharged back into the sea. Additionally, we procure freshwater from Kahramaa, obtained through the desalination of seawater, which is then utilised in our steelmaking, rolling mill, and DRI plants. Due to the nature of the steel making and rolling mill processes, the water evaporates and therefore there is no wastewater generation in these plants. On the other hand, the water used in the DRI plant for cleaning and cooling of reformed gas is then sent to DR water treatment section to abate any ammonia present in the water before being discharged to sea. Part of the treated wastewater is reused in the plant for cooling, irrigation, and other purposes.

Our primary impact stems from the discharge of DR wastewater to the sea. Consequently, our efforts are concentrated on minimising the amount of wastewater discharged by reducing our freshwater requirements, maximising recycling initiatives, and implementing stringent controls to ensure compliance with regulations governing water discharge. By taking these measures, we aim to mitigate our environmental footprint and actively contribute to responsible water management. Currently, the wastewater discharge to the sea is maintaining as per the guidelines set by MoECC. To date, there is zero non-compliance recorded with regards to discharge limit. Discharge of used water (wastewater) has been an issue for industries which not only causes contamination to the environment, but it is also a resource and monetary loss for the industries. Near Zero liquid discharge (NZLD) is an engineering approach to wastewater treatment where maximum water is recovered, and very minimal amount of wastewater will be discharged to sea. Qatar Steel is in the process of commission a NZLD

Plant which we expect to be operational in 2024.

In 2023, Qatar Steel achieved a 54% increase in the amount of water recycled compared to 2022 recycled volume, primarily attributed to the utilization of wastewater for dust suppression while handling the EAF slag. However, there was a simultaneous 36% rise in freshwater consumption compared to 2022 volume, driven by the operation of previously mothballed plants and related activities.

Though the absolute volume of water recycled/reused witnessed a significant growth of over 54% in 2023 compared to 2022, Qatar Steel has observed a shortfall in achieving its target relative to the percentage of water reused as the NZLD plant is still under commissioning and will be operational in 2024, where we are expecting to reduce the freshwater consumption by 80%. Initial target was to reduce the freshwater consumption up to 88% but during final stage of commissioning it is noticed that maximum recovery from the NZLD plant will be 80% due to feed water quality variation associated with DRI raw material quality. Major issues related to equipment, process, automation etc. were identified during a cold test run. The Original Equipment Manufacture (OEM) were involved to rectify all issues, following which a successful plant equipment cold test run was completed. Currently, hot commissioning is in progress. The Performance Guarantee Test (PGT) is expected to be completed by the end of Q3 2024. The wastewater discharge to the sea is maintained as per the guidelines set by MoECC – Qatar. In 2023, there were no recorded instances of non-compliance with discharge limits.