At Qatar Steel, we have developed a comprehensive procedure to effectively manage the identification, segregation, collection, and disposal of waste generated within our operations.

To ensure proper waste management, our procedures include labelling and inspection of all waste before disposal at compliant storage, treatment, or disposal facilities. We track and document waste movement using a Waste Transfer Note system. This system includes details such as waste description, location, transfer date and time, quantity, driver information, and vehicle registration. Every waste load must be accompanied by a Waste Transfer Note, and contracted waste carriers are required to submit transfer notes at the company’s security gates upon exiting the premises.

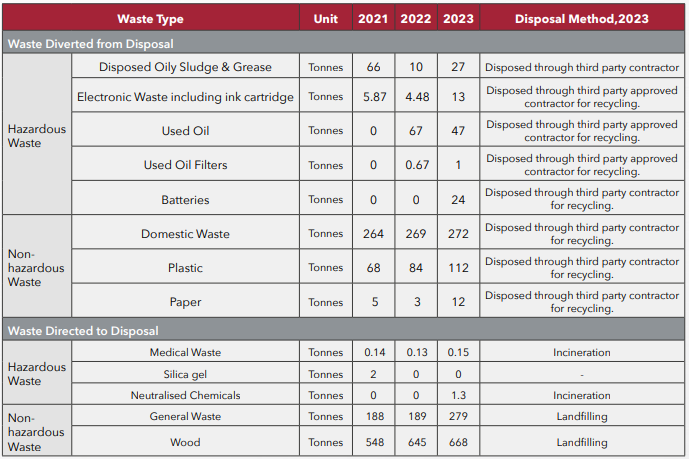

A quarterly report summarising all nonhazardous waste shipments is submitted to MoECC. Hazardous waste is temporarily stored in an approved facility and is disposed of locally through third-party contractors under disposal contracts. The waste contractor submits disposal certifications to verify adherence to waste management protocols. Contractor selection is based on strict technical evaluation criteria, and regular performance reviews are conducted. Periodic visits to waste disposal facilities are conducted to assess compliance and ensure proper handling of waste.

Additionally, the Facilities Department has made continuous efforts in the management of non-hazardous waste. We have implemented waste segregation practices starting from the point of generation. Recyclable waste is diverted to appropriate recyclers using designated containers distinguished by colour codes.

In 2024, Qatar Steel plans to strengthen the management of solid waste in terms of better segregation, collection, and disposal.

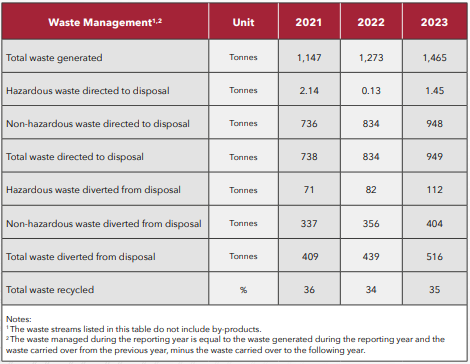

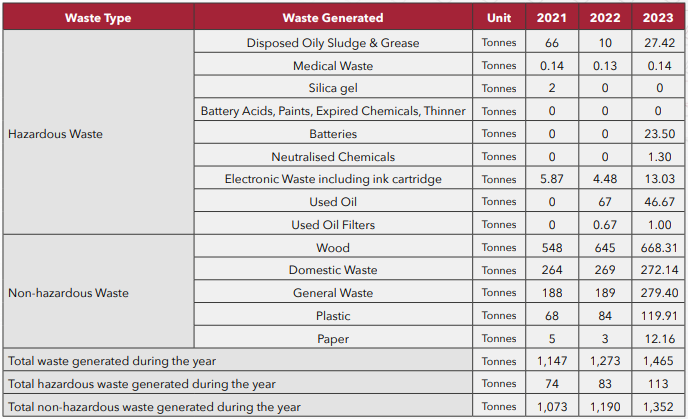

Please find below further details on the waste generated:

To provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.

Employee Portal

Employee Portal