Qatar Steel Product Specifications and Sizes

-

DRI

-

HBI

-

Billet

-

Rebar

-

Wire Rod and Rebar in coil

-

Calcined Lime

-

Dololime

-

Pulverized Limestone

DRI - Sponge Iron

Our DRI Analysis shows high metallization and low gangue, which meet the requirements of steel making operation. The typical quality of sponge produced from MIDREX plant at Qatar Steel.

| DRI Specification | ||

| Guaranteed | Expected | |

| Chemical Composition | ||

|---|---|---|

| Total Iron (T. Fe) | 90.5% Min | 90.5~91.5% |

| Metallic Iron (M.Fe ) | 84.0% Min | 84.0~85.0% |

| Metallization | 92.5% Min | 92.5~94.0% |

| Carbon (C) | 2.20% Min | 2.20~2.50% |

| Phosphorous(P) | 0.06% Max | 0.04% |

| Sulphur (S) | 0.01%Max | 0.002% |

| Total Gangue (CaO+Al2O3+MgO+siO2) | 4.8%Max | 3.80~4.30% |

| Physical Analysis | |

|---|---|

| Bulk Density (Tons/M3) | 1.6~1.9 |

| Size Under 5mm at Loading Port | 5.0%Max |

| Material Safety Data Sheet (MSDS) | |

|---|---|

| MSDS for DRI | |

Hot Briquetted Iron (HBI)

| HBI Specifications | ||

| Chemical Composition | Guaranteed | Expected |

|---|---|---|

| Total Iron (T. Fe) | 90.5% Min | 90.5~91.5% |

| Metallic Iorn (M.Fe) | 84.0% Min | 84.0~87.0% |

| Metallization | 92.5% Min | 92.5~94.0% |

| Carbon (C) | 0.90% Min | 1.1~1.3% |

| Phosphorous (P) | 0.06% Max | 0.04% |

| Sulphur (S) | 0.01% Max | 0.002% |

| Total Gangue (CaO+Al2O3+MgO+SiO2) | 4.8% Max | 3.80~4.30% |

| Physical Analysis | |

|---|---|

| Bulk Density (Ton/M3) | 2.4 ~ 2.7 |

| Apparent Density | 5.0 ton/M3 Min |

| Average Size (mm) | 106 x 48 x 32 |

| Size Under 1/4 Inch at Loading Port | 5.0% Max |

Steel Billets

Although some of the billets produced at Qatar Steel are sold directly to customers, most are processed into bars in our rolling mills. We supply high quality steel billets of various cross-sections and sizes, which enable us to meet the customer requirements and industry specifications.

Permissible variations from specified ranges and marketing's are tabulated.

| Steel Billet Specification | ||||||||||

| Chemical Composition | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| (As per below or as per customer requirement) | ||||||||||

| Chemistry | %C | %Si | %Mn | %P | %S | N(ppm) | ||||

| 0.15~0.25 | 0.12~0.20 | 0.60~0.80 | 0.035max | 0.035max | 120 max | |||||

| Note: Tramp Elements (Ni + Cr + Cu + Mo) = 0.30% max |

||||||||||

| Physical Parameters | ||||

|---|---|---|---|---|

| Sr. No. | Item | Acceptance Criteria | ||

| 1. | LENGTH | 3.8 meter to 12 meter (± 50mm) for 150 x 150mm² section) 6.0 meter to 12 meter (± 50mm) for 130 x 130 mm² section) |

||

| 2. | SECTION | 150 x 150mm2 or 130 x 130mm2 | ||

| 3. | FACE LENGHT | ± 3mm | ||

| 4. | RHOMBODITY | 5% Max | ||

| 5. | CORNER RADIUS | 8mm | ||

| 6. | STRAIGHTNESS | Camber 5mm/meter | ||

| 7. | BENDING | Not more than 5mm in 1 meter Not more than 30mm in 6 meter Not more than 60mm in 12 meter |

||

| 8. | ANGULAR TWIST | Not more than 1º / meter and Not more than 6º over 12 meter length. |

||

| 9. | CUTTING | Both ends will be Gas Cut | ||

| 10. | IDENTIFICATION | At the end of each billet cast number will be stamped or written by paint | ||

| 11. | SURFACE & INTERNAL QUALITY |

The billets will be free from surface imperfections which impair the product quality such as longitudinal cracks, transverse cracks, Deep ripple mark, scab & thick scale, slag patches, surface blow holes & Internal quality should be free from harmful defects such as subsurface pinholes, blow hole, pipes, voids, and internal crack.

As Qatar Steel have open casting process, chances of minor surface pinholes is there and it will not impair the product quality.

|

||

| Note: % Rhombodity = [(DMax - DMin)/ DMax] * 100 |

||||

Reinforcing Steel Bars (Rebars)

Advanced technology to meet the market requirements and superior surface quality are some of the prominent features of Qatar Steel’s rebar.

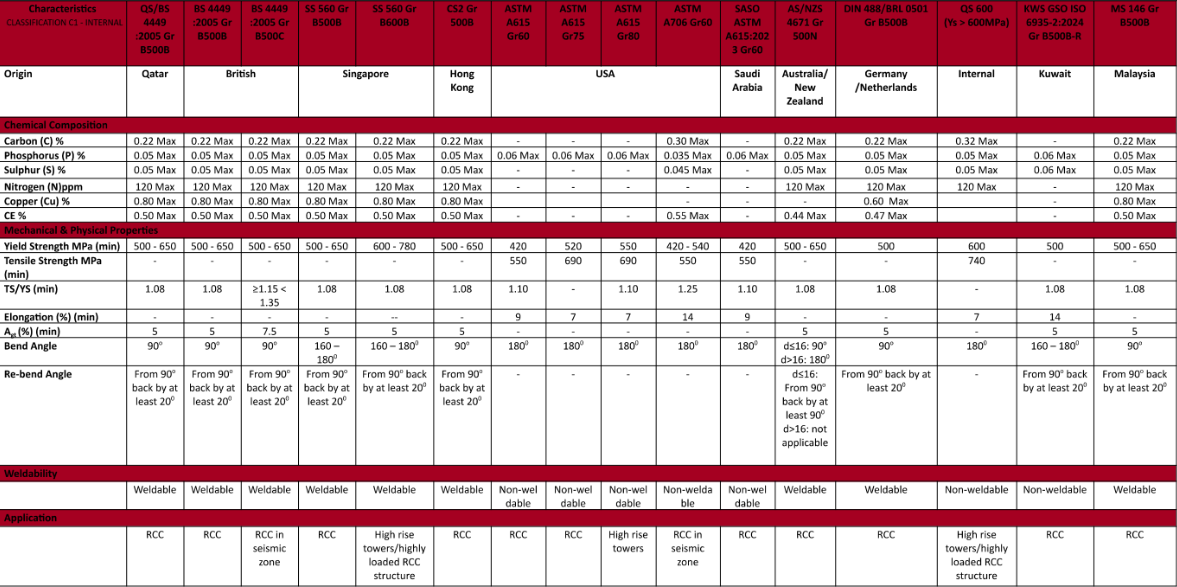

Rebar Specifications

- Bend and Rebend tests are performed as specified inrespective standards using proper mandel diameters

- Rub/Surfaces geometry and weight tolerance are maintained as per the relevant product standards

| Technical Features | |

|

|

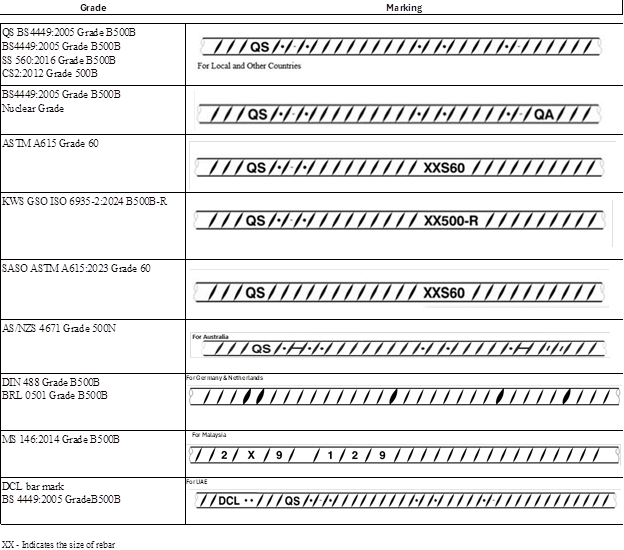

Rebar Marking

Deformed bars produced at Qatar Steel conform to various national and international standards such as, BS 4449:2005 Grade B500B/Grade B500C (Nuclear Grade & British)/QS BS 4449:2005 Grade B500B, SASO ASTM A615:2018, ASTM A615 Grade 40/Grade 60/Grade 75/Grade 80 (American) & QS 600 (Qatar Steel High strength rebar).

The registered trade mark ‘QS’ is embossed on every rebar at an interval of about one meter along with the relevant identification marks

| Wire-Rod and Re-Bar In Coils | ||||||||||||

| Product Size | ||||||||||||

| Products | Size - MM | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wire Rod | 5.5 | 6.0 | 6.5 | 7.0 | 8.0 | 9.0 | 10 | 11 | 12 | 14 | 16 | - |

| Rebar in Coil | -- | -- | -- | 7.0 | 8.0 | - | 10 | - | 12 | 14 | 16 | - |

Wire Rod Grades: SAE1006/ SAE1008/ SAE1012/ SAE1018/ SAE1042/ SAE 1045/ SAE1060/ SAE1065/SAE1070/ SAE1080

| Rebar in Coil: ASTM A615 GR60/ BS4449:1997: GR460B / BS4449:2005 GRB500B / ISO 6935-2 | |

| Coil Weight & Dimension | Metallurgical Standard |

|---|---|

| Inner Diameter (MM): 850 – 950 | Decarburization : 1% max of wire rod diameter |

| Outer Diameter (MM): 1100-1200 | Surface Defect : 1% max of wire rod diameter |

| Coil Weight (Kg) : 1050 -1200 | Cold Up-settability : 67% (Billet route ) |

| Chemical & Mechanical Properties | |||||||||

| Grade | %C | %Mn | %Si | %P | %S | Ys-N/mm2 | Ts-N/mm2 | %El | %Agt. |

|---|---|---|---|---|---|---|---|---|---|

| SAE 1006 | 0.08 Max. | 0.25 – 0.40 | 0.15 Max | 0.035 Max | 0.025 Max | 240 – 290 | 340 – 415 | 35 Min | - |

| SAE 1008 | 0.06 – 0.10 | 0.30 – 0.50 | 0.15 Max | 0.035 Max | 0.025 Max | 250 – 300 | 350 – 425 | 30 Min | - |

| SAE 1012 | 0.10 – 0.15 | 0.30 – 0.60 | 0.15 Max. | 0.035 Max | 0.025 Max | 275 – 325 | 400 – 475 | 30 Min | - |

| SAE 1018 | 0.15 – 0.20 | 0.60 – 0.90 | 0.10-0.35 | 0.035 Max | 0.025 Max | 300 – 350 | 450 – 525 | 22 Min | - |

| ASTM A615 GR60 | 0.22Max. | 0.60 – 1.00 | 0.35 Max | 0.035 Max | 0.025 Max | 420 Min. | 620 Min. | 9 Min. | - |

| BS4449: 1997 GR460B | 0.22Max. | 0.60 – 1.00 | 0.35 Max | 0.035 Max | 0.025 Max | 460 Min. | Ys x 1.08. Min | 14 Min. | 5% Min |

| BS4449 :2005 GRB500B | 0.22Max. | 0.60 – 1.00 | 0.35 Max | 0.035 Max | 0.025 Max | 500-650. | Ys x 1.08 Min. | - | 5% Min |

| Dimensional Tolerances of Wire Rods: | |||||||||

| Standard | Wire Rod Size (mm) | Tolerance +/- (mm) | Out of Round (mm) | Remarks | |||||

|---|---|---|---|---|---|---|---|---|---|

| QS FZE | 5.5 - 16.0 | 0.20 | 0.30 MM | QS FZE Tolerance is Half of ASTM Tolerance | |||||

| ASTM A510 | 5.5 - 16.0 | 0.40 | 0.60 MM | General requirements | |||||

Coil Identification

Each coil will have tag with unique coil number and Heat number.

SPECIFICATION OF CALCINED LIME

| Chemical Composition | |

|---|---|

| Calcium Oxide (CaO) | 92.0% Min |

| Magnesium Oxide (MgO) | 2.0% Max |

| Silica (SiO₂) | 1.5% Max |

| Alumina (Al₂O₃) | 0.30% Max |

| Sulfur (S) | 0.06% Max |

| LOI | 5% Max |

| Moisture | 1% Max |

| Physical Properties (Option1) | |

|---|---|

| Size Range | 30 ~ 80 mm |

| Size above 80 mm at Loading Port | 3.0% Max |

| Size below 30 mm at Loading Port | 10.0% Max |

| Physical Properties (Option2) | |

|---|---|

| Size Range | 3 ~ 30 mm |

| Size above 30 mm at Loading Port | 3.0% Max |

| Size below 3 mm at Loading Port | 10.0% Max |

SPECIFICATION OF DOLOLIME

| Chemical Composition | |

|---|---|

| CaO | 54.0% Min |

| MgO | 32.0% Min |

| SiO₂ | 2.5 Max |

| Al₂O₃ | 0.5% Max |

| Phosphorous (P) | 0.035% Max |

| Sulphur (S) | 0.035% Max |

| Fe₂O₃ | 0.5% Max |

| LOI (at Load Port) | 5.0% Max |

| Physical specification | |

|---|---|

| Size Range | 5 mm ~ 80 mm |

| Size Under 5 mm at Loading Port | 5.0% Max |

| Size Above 80 mm at Loading Port | 3.0% Max |

SPECIFICATION OF PULVERIZED LIMESTONE

| Chemical Composition | |

|---|---|

| Calcium Oxide (CaO) | 50.0% Min |

| Magnesium Oxide (MgO) | 2.5% Max |

| Silica (SiO₂) | 1.0% Max |

| Alumina (Al₂O₃) | 0.5% Max |

| Phosphorus (P) | 0.025% Max |

| Sulfur (S) | 0.05% Max |

| Ferric Oxide (Fe₂O₃) | 2.0% Max |

| Moisture | 0.5% Max |

| Physical Properties | |

|---|---|

| Size above 200 μm at Loading Port | 4.0% Max |